ND Microspheres® Epoxy

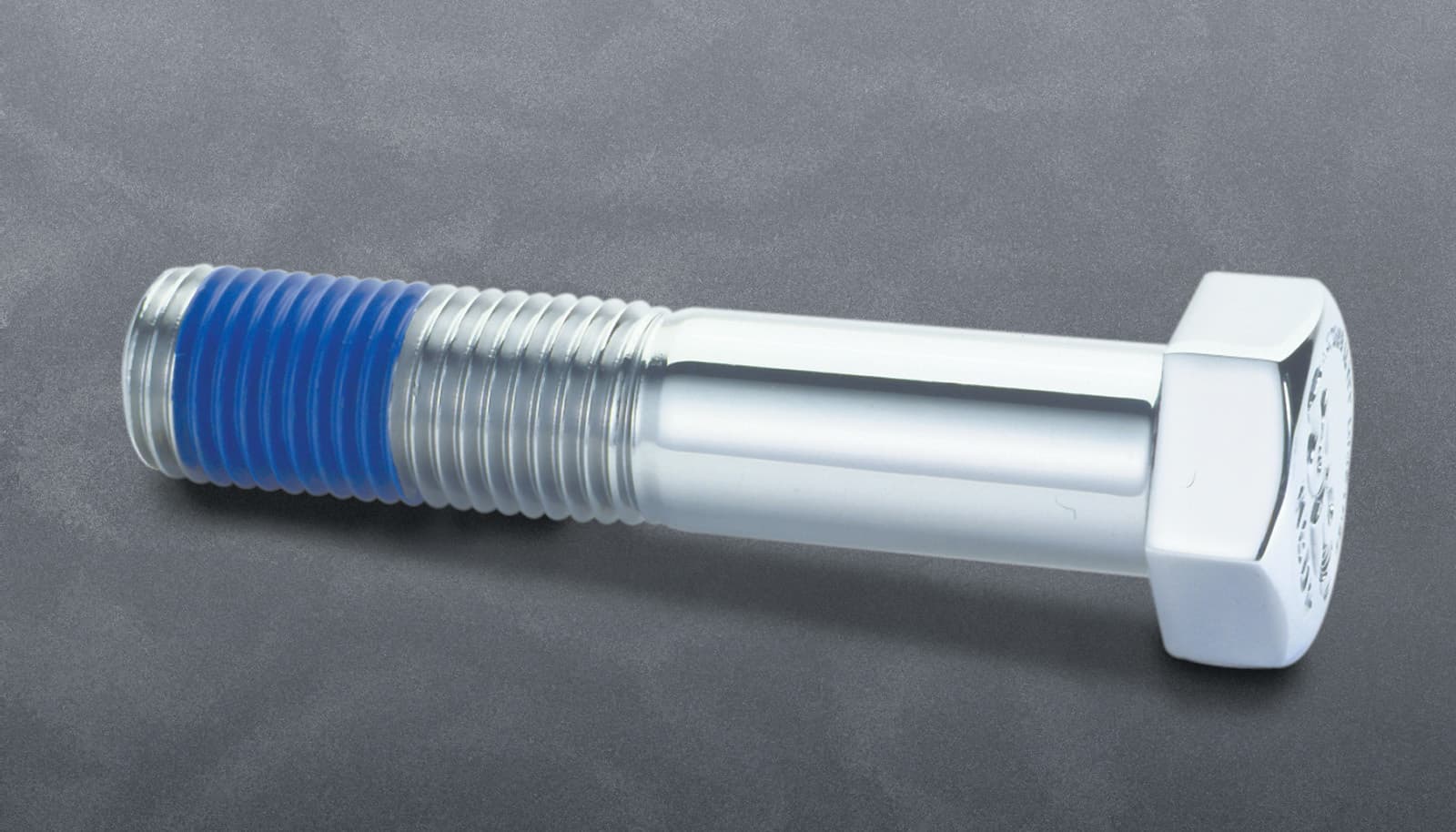

ND Microspheres Epoxy is a pre-applied process in which microencapsulated, epoxy based, room temperature curing threadlocking adhesives are applied to male or female threaded fasteners of virtually all sizes, configurations, materials and finishes.

How it Works

After choosing ND Microspheres Epoxy processing, have your parts sent to one of ND’s service centers. ND will then apply a microencapsulated epoxy resin suspended in a hardener to fasteners. After drying, parts are shipped back to the customer ready for use. When installed, the forces of engagement crush the microscopic capsules of epoxy resin, mix the separate reactant components, and initiate a chemical reaction which locks the parts together.

Versatile

ND Microspheres Epoxy processing is compatible with most fastener sizes, configurations, materials and finishes.

Exceptional Locking

Extensive testing indicates that ND Microspheres Epoxy processed fasteners provide two to four times greater breakaway torque than conventional ``plastic`` thread locking devices.

Resists Chemicals

Processed parts resist and seal against most automotive fluids. Oil, water, antifreeze, and gasoline have virtually no effect on performance once the final cure has been achieved.

Low Prevailing On Torque

Compared to patch threadlockers, ND Microspheres Epoxy fasteners have a lower on torque and assemble easily with common hand tools.

On-Part Life

Materials used for ND Microspheres Epoxy processing will remain inert until a cure is activated by thread engagement.

Surpasses IFI Standards

ND Microspheres Epoxy processed parts meet or exceed all torque requirements of IFI 125, IFI 525, as well as automotive adhesive coated fastener performance specifications.