Stay-Put®

Stay-Put processing adds a temporary, dependable retention device to fasteners or other components. Parts can be sent in for separate processing or to be combined into one assembly by ND; reducing end user assembly time, associated labor costs, and inventory.

How it Works

After discussing your application with our sales team, have your parts sent to one of ND’s facilities for processing. If necessary, we will combine components into one unit and apply one of our custom materials to hold the parts in place. Once processing is complete, we ship your parts back ready for assembly.

Speeds Assembly

Stay-Put processing combines auxiliary attachments, resulting in a reduction of the quantity of parts involved and a decrease in the assembly difficulty.

Reduces Inventory

Pre-assembled auxiliary attachments allow the combining of part numbers resulting in less paperwork and the reduction of shipping costs and storage space.

Consistent Results

ND has a wide range of materials available to meet your exact application needs, including those that involve ferrous and non-ferrous metals, solvents, oil, gasoline, acids, water, salt, and extreme temps.

Reduces Operator Fatigue

Stay-Put assemblies increase overall procedural ergonomics and decrease the number of tasks required to assemble an end product.

Versatile Formulas

Depending on the application requirements, processing can be completed with polyamides, adhesives, UV curable compounds and more.

Customer Assistance

ND’s experienced engineers can help you to perform an efficiency analysis to see how Stay-Put will ensure the most optimized end product fabrication possible.

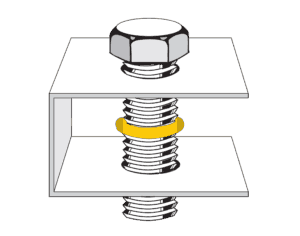

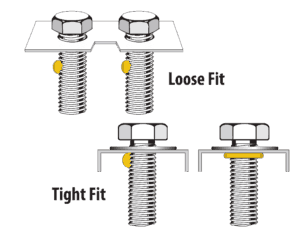

Temporary Fastener Retention

Stay-Put processing can be used to hold fastener(s) in place, making it easy for an operator to complete the assembly process.

Short-Term Unit Adhesion

The Stay-Put application process can be specified to act like a glue, temporarily bonding a number of auxiliary components together.

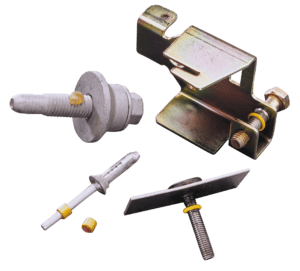

Pre-Assembled Auxiliary Components

Utilize Stay-Put processing to combine numerous parts or auxiliary attachments into one easy-to utilize unit.

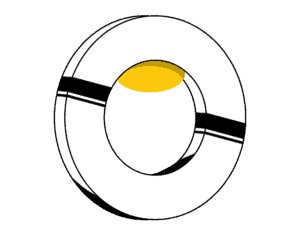

Stay-Put®

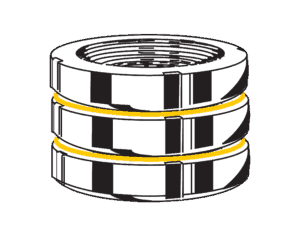

Washer

Assembly aid and SEMS Screw process alternative. Increase the efficiency of your assembly process with the Stay‑Put Washer.