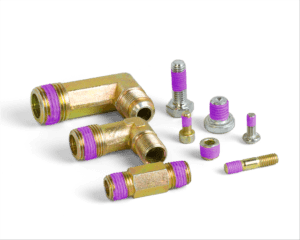

Expand-A-Seal®

Expand-A-Seal is a unique microencapsulated expanding thread sealant which is pre-applied by ND to your fasteners and arrives dry to the touch and ready for assembly. Upon installation Expand-A-Seal increases in volume 20 to 50%, penetrating gaps in fastener threads typically left unfilled by conventional thread sealants. When fully cured it forms a high pressure seal against gas and fluid.

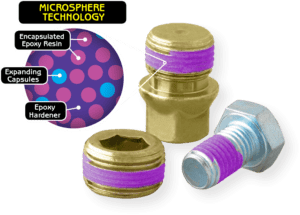

How it Works

Expand-A-Seal contain a microencapsulated epoxy resin and expanding compounds suspended in a hardener. The forces of engagement crush the microscopic capsules of epoxy resin and expansion agent, mixing the separate reactant components, and initiating a chemical reaction. As the reaction is taking place, the material expands, filling the fastener thread gaps while hardening.

Problem Solver

Many threadsealants fail when used in less than optimal conditions, such as misfit parts or threadformed screws. Because of its expansion properties, Expand-A-Seal can overcome these limitations.

High Pressure Seal

Expand-A-Seal has been shown to have some of the highest sealing pressures of all our pre-applied theadsealants with burst pressure in excess of 10,000 psi under challenging conditions.

Chemical Resistant

A cross-linked molecular structure makes it one of the most resistant types of adhesives. Oil, gasoline, salt spray, acids, solvents, and water have virtually no effect on parts when introduced after final cure.

Surface Insensitive

Expand-A-Seal is compatible with most fastener sizes, configurations, materials and finishes. Its epoxy formulation ensures that a strong reliable lock and seal are formed.

Secure Lock

Once cured, a low strength lock is formed which helps prevent loosening under vibration or reversal of stress and greatly reduces the need to retighten fasteners.

Long Shelf Life

Expand-A-Seal has an on-part life of 1 1/2 years and will remain inert until a cure is activated by engagement with a mating thread.