EZ Drive®

EZ Drive (formerly ND WaxLube) is a pre-applied process whereby fasteners are coated with a synthetic, thermoplastic lubricant which increases installation efficiency by serving as an ergonomic assembly aid. It is used to reduce installation torques on thread-forming fasteners, reducing worker fatigue while increasing productivity. EZ Drive is less expensive and easier to use than competitive products.

How it Works

After choosing EZ Drive processing, have your parts sent to one of ND’s regional service centers. ND will then apply the EZ Drive thermoplastic lubricant with our automated equipment, ensuring consistent quality. Once the materials have dried, fasteners are returned to their original container for shipment. Upon arrival, parts are dry to the touch and are ready for immediate installation. EZ Drive is unaffected by exposure to other lubricants, dust and normal shipping conditions.

Controlled Torque

EZ Drive reduces friction by as much as 75% which creates more consistent drive torques and allows assemblers to position fasteners more easily and accurately.

Saves Time & Money

EZ Drive reduces the amount of time and effort required to install fasteners, therefor cutting down on associated labor costs. Clean and dry formulation eliminates the need to clean up lubricant messes.

Long Shelf Life

EZ Drive processed fasteners are stable and exhibit a virtually unlimited* shelf life when stored in a cool and dry location.

Threadforming Lubricant

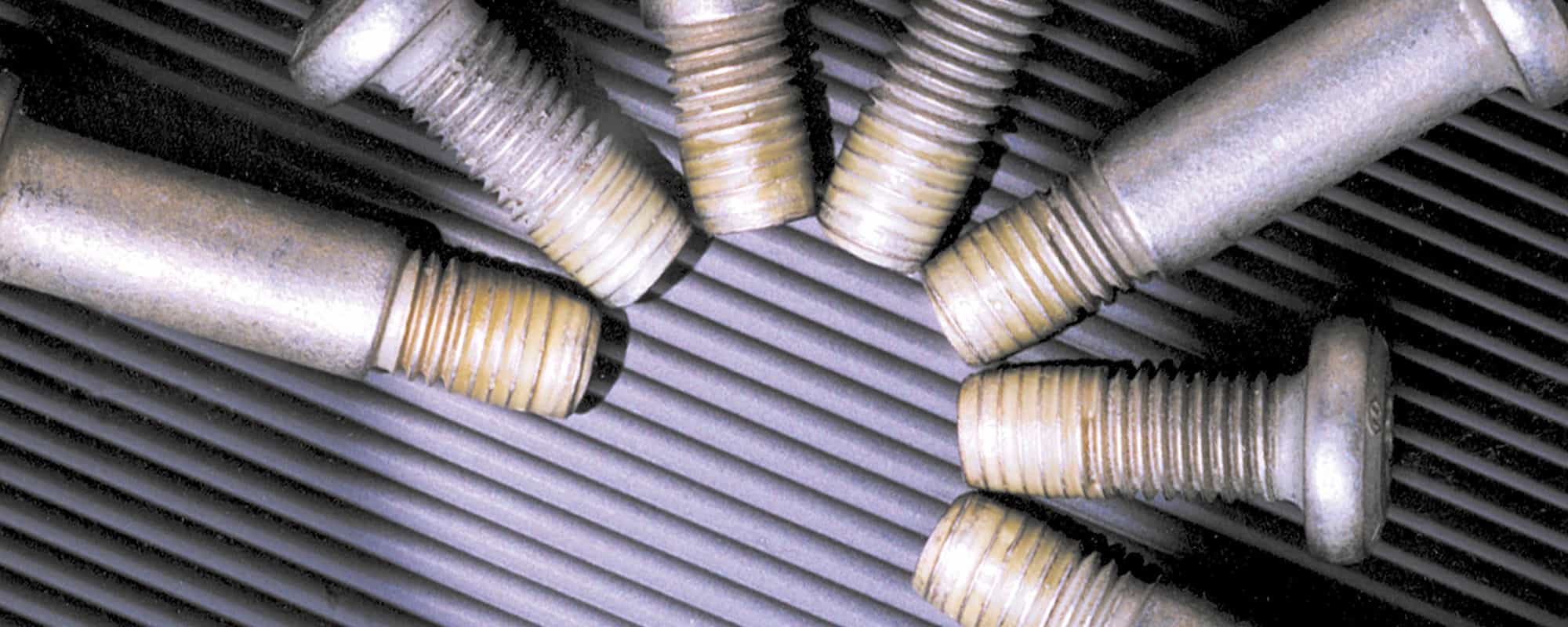

Used on Trilobular®, Taptite®, Taptite II®, and Taptite 2000®, and captive point bolt / nut plane assemblies that create their own threads by distorting a threadless nut into the spaces around the bolt.

Multi-Process Compatible

Can be combined with other ND pre-applied processes to add self-locking and sealing features to fasteners.

Safe and Productive

EZ Drive materials are is non-toxic, nonhazardous, and does not out-gas during assembly. Lower drive torque leads to reduced operator fatigue and associated injuries.