HQ Self-Locking Inserts

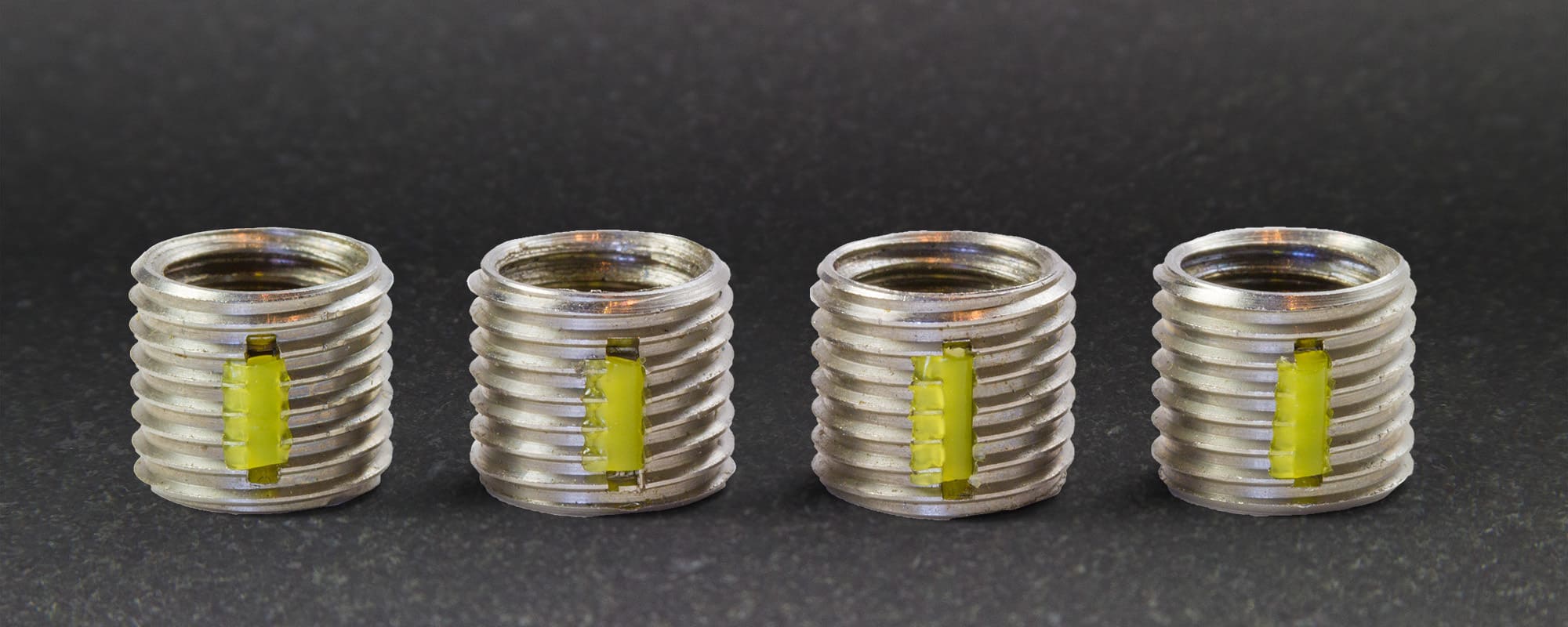

ND “HQ” (High-Quality) Self-Locking Threaded Inserts are constructed of lightweight molybdenum, disulfide coated, stainless steel with a nylon strip element that provides positive locking action for both internal and external threads. ND’s strip-type nylon locking element extends completely through the insert wall.

How it Works

During initial assembly, the nylon element is forced inward until it protrudes beyond the inner threads. When the mating fastener is installed, the locking element enhances metal-to-metal contact, both internally and externally. External prevailing torque is double the internal torque which prevents unintentional rotation of the insert after installation.

Reusable

ND's HQ Inserts can be reused repeatedly, making them ideal for use with low tensile strength materials such as aluminum, magnesium, and plastics.

Easy to Use

Installing ND HQ Self-Locking Threaded Inserts is as easy as using a standard drilling tool to drill, tap, and assemble.

Hi-Temp Materials

The normal temperature range for ND HQ Self-Locking Threaded Inserts is -60°F to +250°F (-45.5°C to +121°C). However, inserts are available in other materials to meet special services requirements.

Reclaim Stripped Threads

ND HQ Threaded Inserts offer a simple, inexpensive way to reclaim stripped threads on expensive components or subassemblies.

Corrosion Resistance

Unlike conventional inserts which require tapping or drilling, ND HQ self-locking inserts do not damage mating part finishes.

Increased Joint Strength

ND HQ Inserts can be used on low tensile strength materials to increase their strength and durability.